GL-400H 2 in 1 Uncoiler And Straightener Equipped With Coil Feeder For Metal Stamping

- Model

- GL-400H

Item specifics

- Function

- decoiling metal coils for stamping

- Feature

- combined decoiler straightener

- Name

- decoiler straightener machine for stamping

- Compact

- servo coil feeder machine

- Usage

- metal coil handling equipment

- attribute

- automation stamping line

Review

Description

GL-400H 2 in 1 Uncoiler And Straightener Equipped With Coil Feeder For Metal Stamping

Description

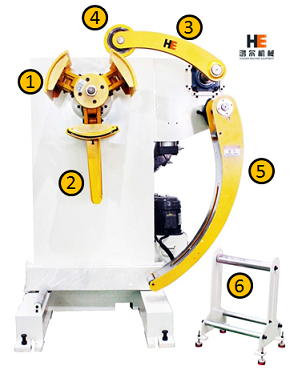

Decoiler Section

1, Decoiler with hydraulic expansion for coil unwinding;

2, Coil keeper to allocate the coil sheet;

3, Pressing arm to press coil;

4, PU wheel protecting the surface of coil when feeding;

5, Supporting arm with pneumatic to lift coil;

6, Induction pole to help feed speed controlling.

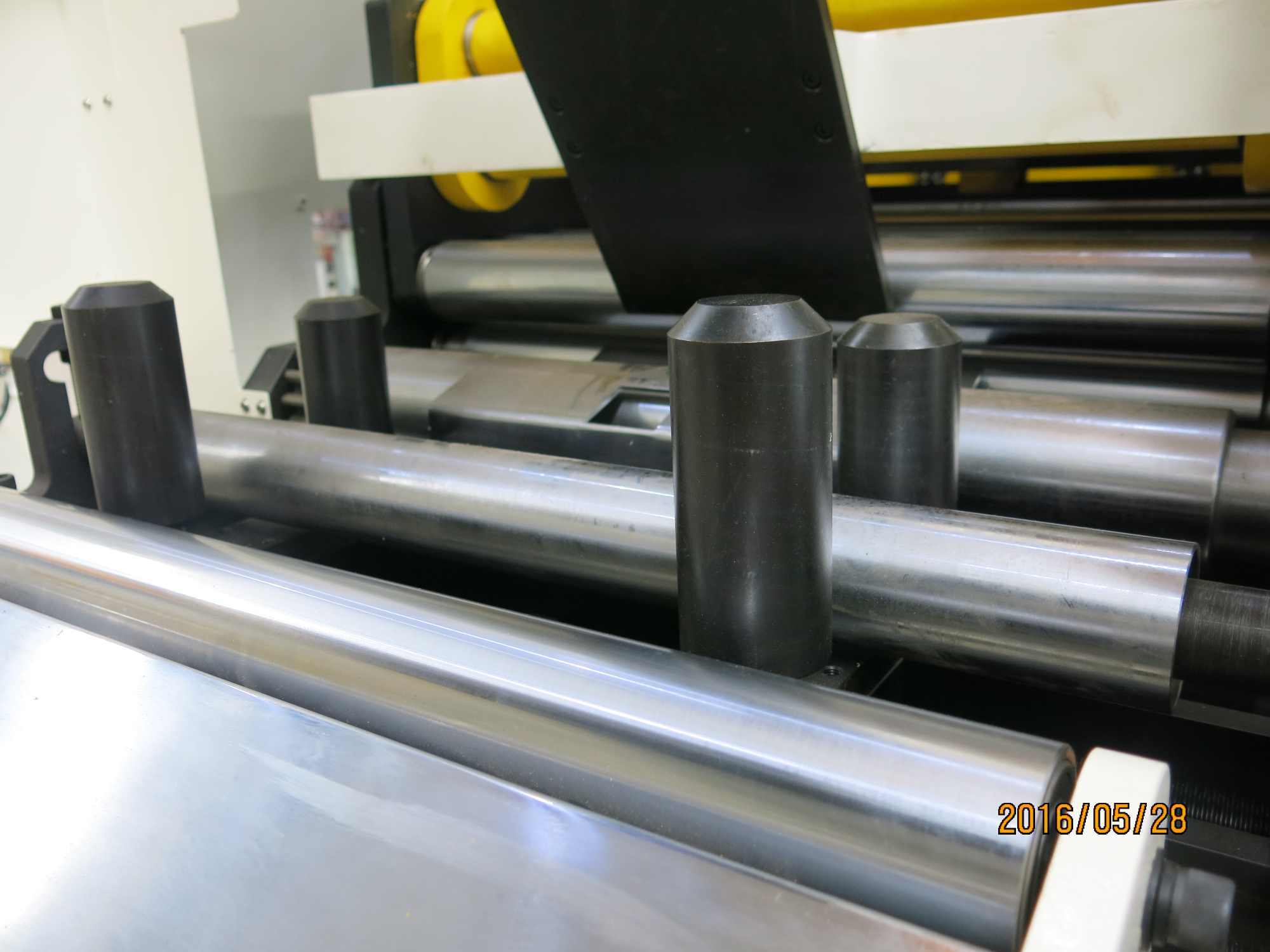

1, Feeder inlet with coil inlet arm;

2, Hand wheel to control the stop rollers which can allocate the strip;

3, Worm & gear adjustment to adjust the gap between straightener rollers which makes operation easier and more precision performance;

4, Feeder outlet;

5, Control systerm.

specification

Model |

GL-400H | GL-600H | GL-800H |

Coil width(mm) | 400 | 600 | 800 |

Coil thickness(mm) |

0.5-4.5(6.0) |

||

Coil weight(kg) | 3000 | 5000 | 7000 |

Coil I.D(mm) | 460-520 | ||

Coil O.D(mm) | 1200 | ||

Speed(m/min) |

16 |

||

Straightener roller |

4 on top / 3 on bottom Bottm rollers have drive function |

||

Pinch roller | Inlet: 2 / Outlet: 2 | ||

Servo motor(KW) | 2.2 | 5.5 | 5.5 |

Uncoiler motor(KW) | 1.5 | 2.2 | 2.2 |

Mandrel expansion | hydraulic | ||

Detail Photo Show

Application

GL-H heavy coil loaded decoiler straightener machine which is widely used in metal stamping line with thickness from 0.5-4.5mm. It is popular in electric appliance, construction, furniture industry, clothing metal parts, auto parts stamping etc.

GL-400H

for metal stamping line

in automotive stamping manufacture

exported to South Africa

Metal stamping solution suggestion:

GL-H+ NC servo feeder + Press

Solution suggestion

Package & Delivery