GLK2 Unit Decoiler Straightener Feeder Machine With Press For Electrical Components Stamping Line

- Model

- GLK2

Item specifics

- Function

- auto decoiler straightener

- Feature

- Stamping for metal coil feeder

- Name

- Uncoiler straightener feeder

- Compact

- with metal press machine

- Usage

- metal steel fabrication with stamping

- attribute

- 3 in 1 decoiler straightener feeder

Review

Description

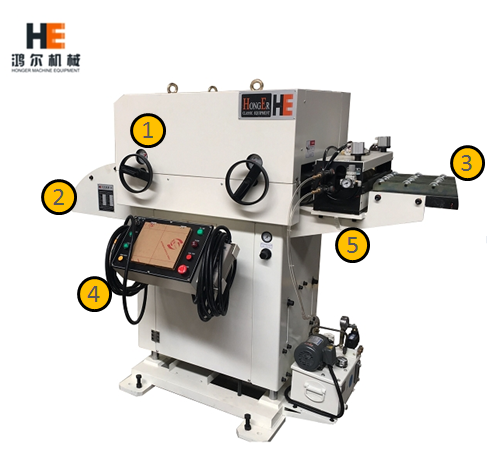

GLK2 Unit Decoiler Straightener Feeder Machine With Press For Electrical Components Stamping Line

Description

Decoiler Section

1, Pressing arm to press coil;

2, PU wheel on the pressing arm, so as to protect the surface of coil;

3, "A" frame coil keeper to locate coil;

4, Decoiler mandrel with hydraulic expansion and delta inverter;

5, Supporting arm with pneumatic to lift coil;

Straightener & Feeder Section

1, Worm & gear adjustment to adjust the gap between straightener rollers;

2, Feeder inlet can be customized with coil inlet arm;

3, Outlet support bracket can be customized with the length;

4, Display screen is from Weinview Taiwan;

5, Oil car is optional which can protect the moulds;

specification

Model |

GLK2-300 | GLK2-400 | GLK2-500 | GLK2-600 |

GLK2-700 |

GLK2-800 |

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | |||||

Coil width(mm) |

50-300 | 50-400 | 50-500 | 50-600 |

50-700 |

50-800 |

Coil thickness | 0.3-3.2mm | |||||

Coil weight | 2000kg | 3000kg | 5000kg | |||

Coil I.D.(mm) |

480-520 |

|||||

Coil O.D.(mm) |

1200 |

|||||

Max. speed | 20 m/min | |||||

Feeding accuracy | +/- 0.1 mm | |||||

Straightener rollers | 6 rollers on top 5 rollers on bottom | |||||

Power | 380V 60HZ | |||||

Expansion | Hydraulic | |||||

Pressing arm | Pneumatic Type | |||||

Servo motor | AC1.8 KW | AC2.9 KW | AC4.4 KW | AC5.5 KW | ||

Uncoiler motor | AC1.5KW | AC2.2 KW | AC3.7 KW | |||

Features

GLK2 series 3 in 1 servo coil feeder machine:

3 in 1 decoiler straightener feeder machine:

1, full automation function

2, decoiling straightening feeding metal coils

3, suitable for metal steel like low carbon steel, high carbon steel, cold rolled steel, hot rolled steel

4, handle with heavy duty metal coils

5, easily operating with control panel

6, decoiler straightener and feeder are controlled by the same signal, so as to make high synchronous

7, without second deformation ( compared with single machine, there is a loop between straightener and feeder)

8, save work space

9, save labor cost

10, compact with progressive mold for metal stamping to increase production capacity

Package & Delivery