GLK3-400 3 in 1 Unit Feeder for Metal Coil Pressing In Automation Feeding System

- Model

- GLK3-400

Item specifics

- Function

- automation feeding

- Feature

- Servo Straightener Feeders

- Name

- 3 In 1 straightener Feeder

- Compact

- Coil Handling Equipment

- Usage

- for auto parts stamping

- attribute

- Sheet Metal Feeding Equipment

Review

Description

GLK3-400 3 in 1 Unit Feeder for Metal Coil Pressing In Automation Feeding System

Description

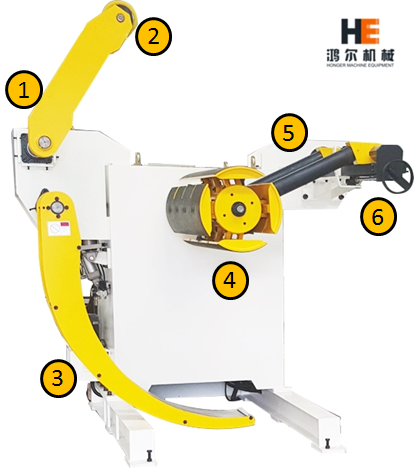

Decoiler Section

1, Pressing arm with pneumatic to press coil;

2, PU wheel on the pressing arm, so as to protect the surface of coil;

3, Supporting arm with pneumatic to lift coil;

4, Decoiler mandrel with hydraulic expansion and delta inverter;

5, Coil keeper with pneumatic to locate coil;

6, Hand wheel for centring adjustment.

Straightener & Feeder Section

1, Feeder inlet;

2, Coil inlet arm for coil feeding assistant;

3, Hand wheel to control the stop rollers which can allocate the strip;

4, Display screen is from Weinview Taiwan;

5, Worm & gear adjustment to adjust the gap between straightener rollers;

6, Outlet support bracket can be customized with the length;

Specification

Model |

GLK3-400 | GLK3-600 |

GLK3-800 |

GLK3-1000 |

Coil width(mm) |

50-400 | 50-600 |

50-800 |

50-1000 |

Coil thickness(mm) |

0.3-4.5 | 0.3-4.5 |

0.3-4.5 |

0.3-4.5 |

Coil weight(kg) |

3000 | 5000 |

7000 |

7000 |

Coil I.D.(mm) | 480-520 | |||

Coil O.D.(mm) | 1200 | |||

Feeding pitch(mm) | 0-500 | |||

Speed(m/min) | 16-24 | |||

Straightener roller(pc) | 4 on top / 3 on botton | |||

Feeding roller(set) | 1 | |||

Servo motor(KW) | AC4.4 | AC4.4 | AC5.5 | AC5.5 |

Uncoiler motor | AC2.2 | AC2.2 | AC3.7 | AC3.7 |

Expansion | Hydraulic | |||

Power(V) | 220/380 | |||

Operating Air(Mpa) | 0.49 | |||

Features

GLK3 series of unit coil feeder machine:

1, combined decoiler, straightener and feeder to save work space and make the whole line speed synchronous with press machine

2, with full automation function of uncoiling, straightening, feeding

3, handling the metal coil sheet with 0.5-4.5mm thickness

4, large capacity of decoiler mandrel could carry up to 10 tons weight of metal coil

5, coil car to help metal coil upload and save time for material changing. Meanwhile, make the job more safety and easy opreation

6, safety guard could be customized if needed

7, ground pit may needed if the metal coil OD is as large as 1800mm or the feeding pitch is over 500mm. Ground pit will help to make longer metal coil sheet so as to keep the speed of punching

8, coil keeper adjusted by hand wheels, but electrical adjustment is optional

9, straightener roller adjusted by worm and gear. electrical adjustment could be customized

10, feeding height can be adjusted in range +/-100mm to make equal to the lower die height of press machine

11, hydraulic shearing is optional for metal coil head cutting

12, lubrication device is optional if needed to protect press tooling

Application

GLK3-400 is uncoiling straightening and feeding metal coils with 400mm width in press room. It realizes automation feeding when equipped with press machine. It is compacted with mechanical / hydraulic press machine and used in construction metal parts line, automobile stamping line, furniture stamping line.

GLK3-400F

Customized GLK3-400

3 in 1 unit feeder with press machine for automation feeding system

in auto parts stamping line

exported to UK

Metal stamping solution suggestion:

3 in 1 servo feeder + press machine

Package & Delivery