GLK3-1300 Unit Coil Feeder Machine Compact Press Punching For Cover Of Air Conditional

- Model

- GLK3-1300

Item specifics

- Function

- Automatic Metal Sheet Coil Feeding

- Feature

- Servo Straightener Feeder

- Name

- 3 In 1 Compact Straightener Feeder

- Compact

- Steel Coil Handling Equipment for Press

- Usage

- For Auto Parts And Steel Works Stamping

- attribute

- Metal Strip Coil Feeding Equipment

Review

Description

GLK3-1300 Unit Coil Feeder Machine Compact Press Punching For Cover Of Air Conditional

Description

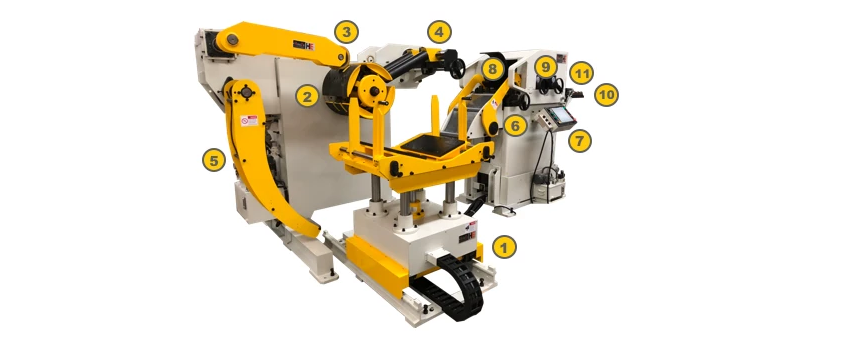

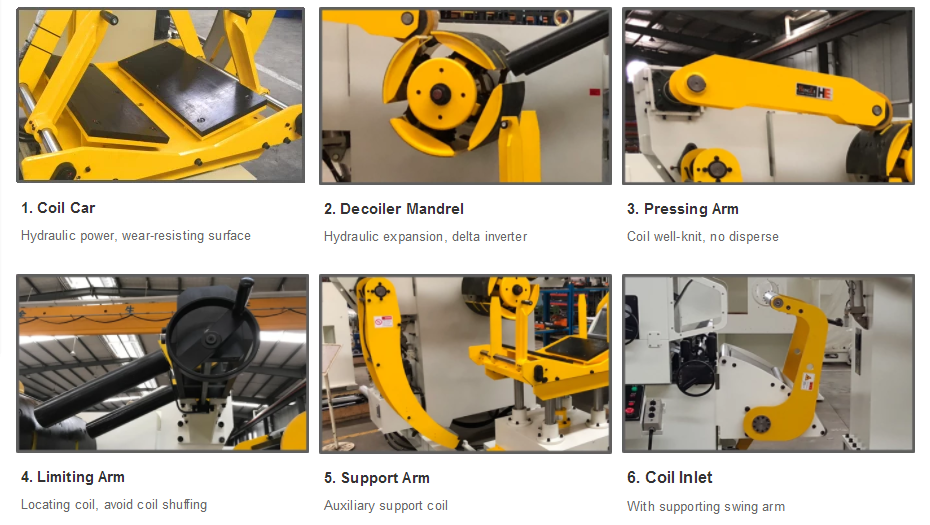

Details Show

Specification

Model |

GLK3-1300 |

|||

Coil width(mm) |

50-1300 |

|||

Coil thickness(mm) |

0.3-4.5 |

|||

Coil weight(kg) |

10000 |

|||

Coil I.D.(mm) | 480-520 | |||

Coil O.D.(mm) | 1200 | |||

Feeding pitch(mm) | 0-500 | |||

Speed(m/min) | 16-24 | |||

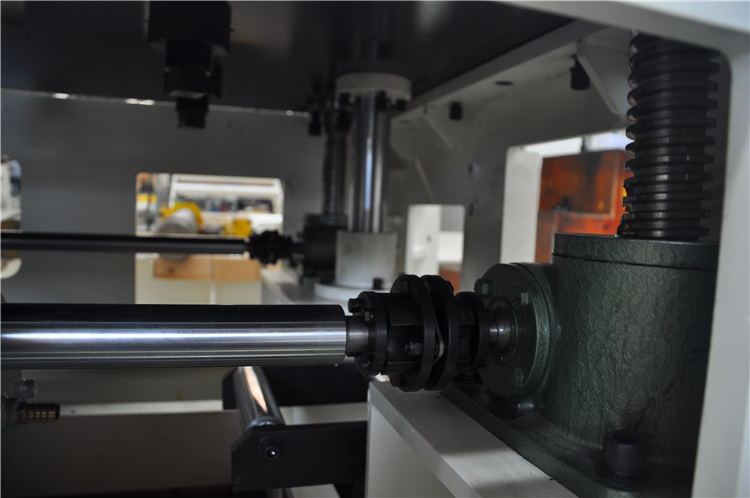

Straightener roller(pc) | 4 on top / 3 on botton | |||

Feeding roller(set) | 1 | |||

Servo motor(KW) | AC5.5 | |||

Uncoiler motor | AC3.7 | |||

Expansion | Hydraulic | |||

Power(V) | 220/380 | |||

Operating Air(Mpa) | 0.49 | |||

Application

GLK3-1300 is suitable for large capacity of metal coil handling. It works for max 1300mm width coil sheet with 0.3-4.5mm thickness. It can be compact with mechanical press for blanking, punching, metal forming, deep drawings, etc. It is widely used for automotive stamping line or for electric application.

GLK3-1300

GLK3-1300 coil feeder equipped with hydraulic shearing with press machine for cover blanking line

Metal stamping solution suggestion:

3 in 1 unit coil servo feeder + press machine

Package & Delivery