DBMT-300 Double Head Decoiler For High Speed Stamping Line

- Model

- DBMT-300

Item specifics

- Function

- Metal Coil Double Head Decoiler

- Feature

- Automatic Double Decoiler

- Name

- Automatic Motorised Double Mandrel Uncoiler Machin

- Compact

- Straightener and servo feeder

- Usage

- DBMT Uncoiler

- attribute

- Double Coil Uncoiler Machine

Review

- P***n

- 2024/1/22 12:17

I need details of the machine. and machinery quotations

Description

DBMT-300 Double Head Uncoiler For High Speed Metal Stamping

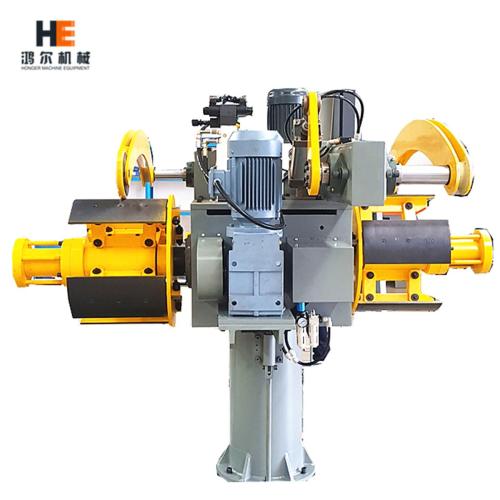

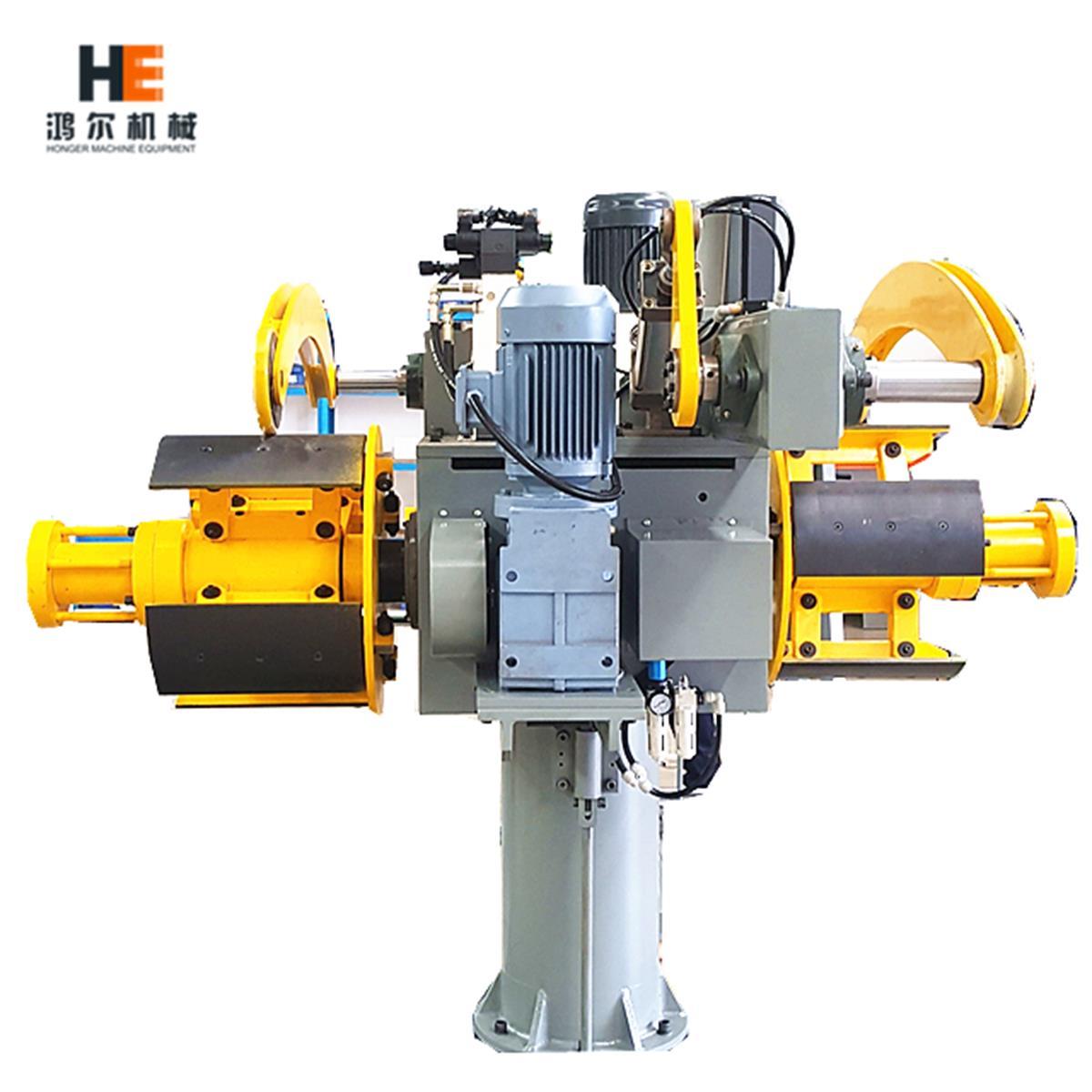

Photo Show

Description

DBMT-300 Double Head Decoiler Machine

1, Suits for sheet metal coil with width 300mm, thickness from 0.35mm to 1.6mm;

2, Used in high speed metal stamping line for stator rotor laminating;

3, Suitable for decoiling the metal material like steel, stainless steel, carbon steel, aluminum, copper, GI steel;

4, Often work with S type straightener and high speed coil feeder;

5, The manual or hydraulic expansion styles for option;

6, With the double head structure, it can save time for loading metal coil sheet.

Specification

Model |

DBMT-200 | DBMT-300 | DBMT-400 |

Coil width(mm) | 200mm | 300mm | 400mm |

Coil thickness(mm) |

0.35-1.6mm |

||

Max outer dia(mm) | 1200mm | ||

Material inner dia(mm) |

450-530mm |

||

Material weight(kg) | 1000kg per side | 1500kg per side | 2000kg per side |

Roller pressure | Spring Type | ||

Mandrel expansion | Manual expansion | ||

Inveter | No | ||

Application

DBMT-300 double head decoiler (unwinder) machine work for high speed stamping line of stator rotor lamination. It is a kind of heavy duty decoiler. With the double mandrel it also can save the loading time. It is often equipped with S type straightener machine and high speed coil feeder for the press. It can handle with most kinds of metal coil strip material, as aluminum sheet, copper strip, stainless steel, carbon steel, mild steel, etc.

DBMT-300

Double head decoiler machine

for 300mm width metal coil sheet

for fast punching

exported to Poland.

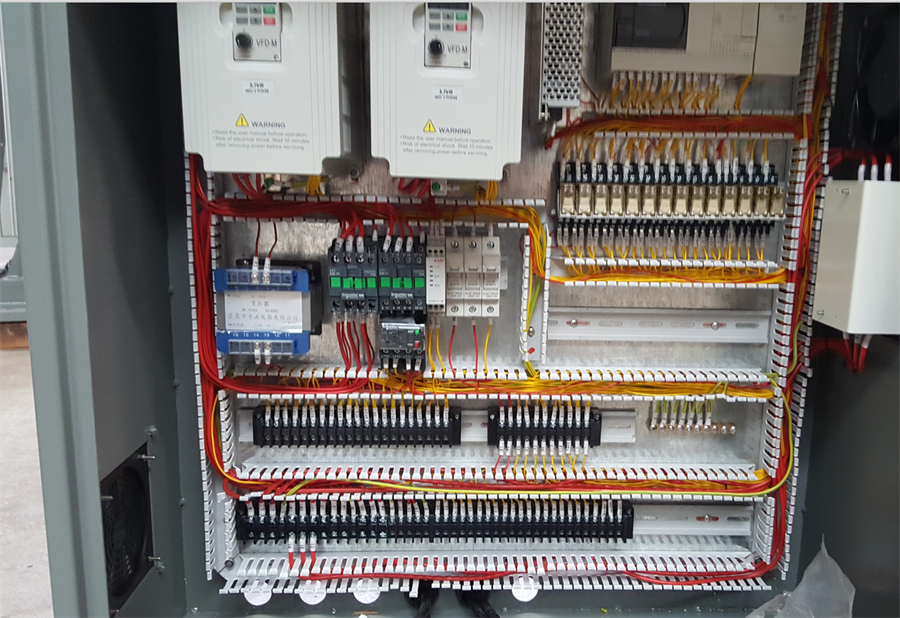

Metal stamping solution suggestion:

Double head decoiler+straightener+feeder + Press

Package & Delivery