GLK-400D Double Head Coil Feeder 3 In 1 Machine For Automobile Stamping Manufacturer

- Model

- GLK-400D

Item specifics

- Function

- faster loading material on decoiler

- Feature

- suitable for automation stamping

- Name

- decoiler straightener auto feeding

- Compact

- mechanical pressing machine

- Usage

- automation feeding in press room

- attribute

- combo servo coil feeder machine

Review

Description

GLK-400D Double Head Coil Feeder 3 In 1 Machine For Automobile Stamping Manufacturer

Description

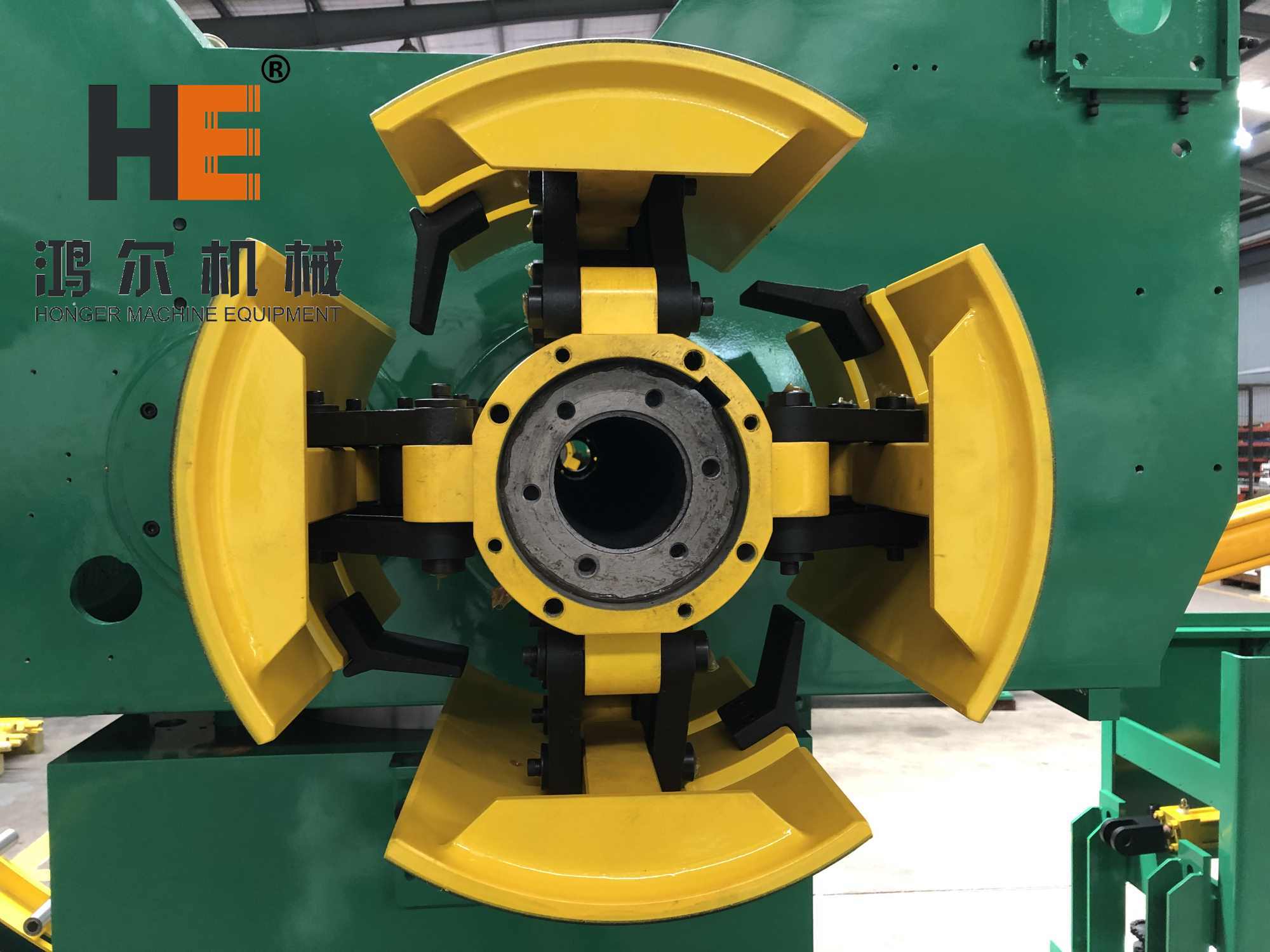

Decoiler part:

1, Pressing arm: with pneumatic power. Especially the PU pressing roller is with motor drive.2, Limited arm: by hand wheel control. Electrical adjustment is optional.

3, Decoiler mandrel: hydraulic expansion.

4, Brake system: Pneumatic disk brake with frequency inverter to protect motor.

5, Double head of decoiler: each side with 5000kg capacity for metal coil

Straightener and feeder part:

1, Inlet feeding arm: clamp the metal coil head and feeding it into straightener (leveler) smoothly.

2, Control display screen: operate the coil feeder machine with electrical control.

3, Straightener: straightener rollers are adjusted by worm and gear. Electrical adjustment is optional if needed. All rollers are made from bearing steel with heat treatment and electroplated chrom achieve to hardness HRC 60-62. Meanwhile, all rollers are have concentricity testing with +/-0.05mm accuracy so as to make high straightening performance.

4, Drive system: striaghtener and feeder shared with Yaskawa servo motor with high precision +/-0.15mm.

5, Outlet: outlet for strip feeding out.

Optional device:

1, Lubrication device: protect the progressive tool

2, Hydraulic shearing: cut the coil head

Standard stamping line:

Double head coil feeder 3 in 1 machine + Mechanical press machine+ progressive tool

specification

Model |

GLK4-400D | GLK4-500D | GLK4-600D |

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | ||

Coil width(mm) |

70-400mm | 70-500mm | 70-600mm |

Coil thickness | 0.6-6.0mm | ||

Coil weight | 5000kg | 5000kg | 5000kg |

Coil I.D.(mm) |

480-520mm |

||

Coil O.D.(mm) |

1500mm |

||

Max. speed | 16-24 m/min | ||

Feeding accuracy | +/- 0.15 mm | ||

Straightener rollers | 4 rollers on top 3 rollers on bottom | ||

Power | 380V 60HZ | ||

Expansion | Hydraulic | ||

Pressing arm | Pneumatic Type | ||

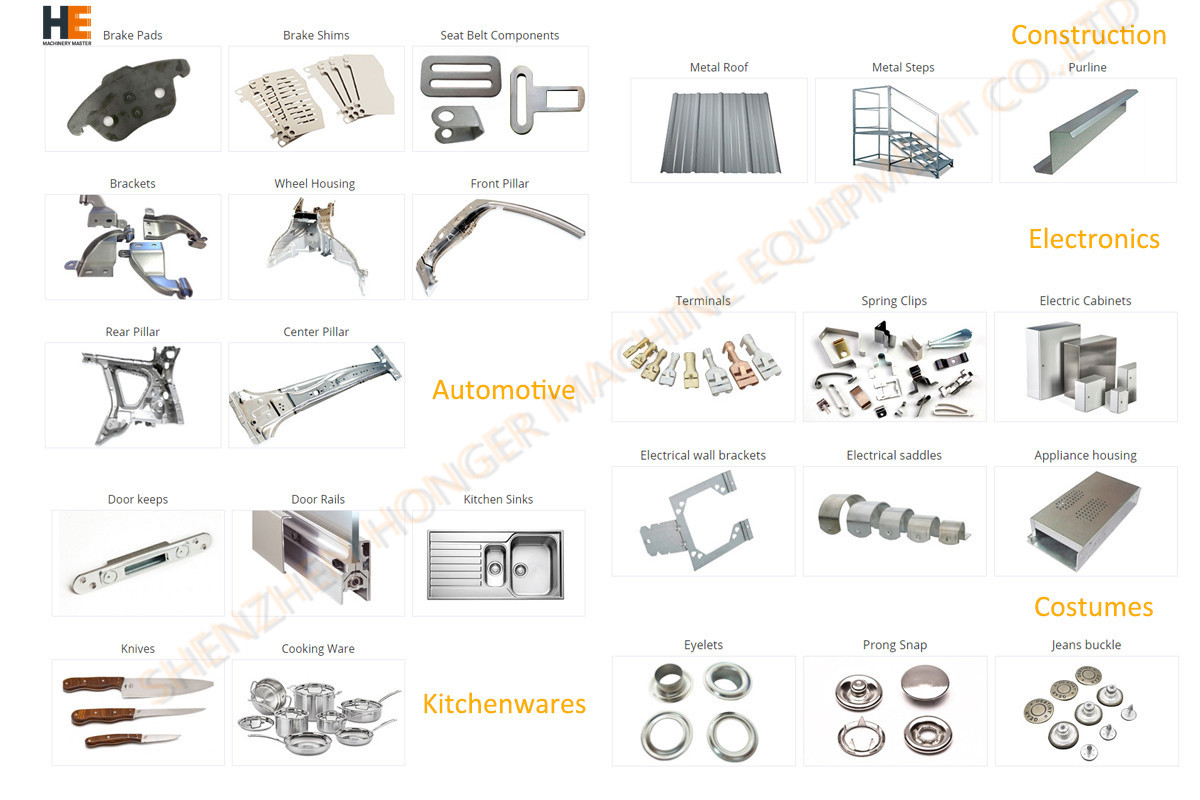

Application

GLK4-400D automation coil feeding line

GLK4-400D uncoiler straightener feeder machine with double coil head to save time of loading which is suitable for auto parts stamping line.

This 3 in 1 auto coil feeder machine can be equipped with press machine, cutting, shearing.

Package & Delivery

About us

www.hongerjixie.com

We are manufacturer of metal stamping equipment like decoiler, straightener, feeder machine for metal coil handling solution in press room.

Our equipment is for automation feeding system in press room to realize automatic stamping.

The related machines of us are including 3 in 1 unit coil feeder, 2 in 1 uncoiler and straightener machine, single decoiler machine, horizontal uncoiler machine, straightener machine, servo coil feeder machine, mechanical press machine, etc.

Our machines are adopted in automotive stamping manufacturer ( automobile manufacturer), construction metal parts manufacturer, furniture metal parts manufacturer, kitchen ware metal parts manufacturer, costume eyelet ( button) manufacturer, electronic parts stamping manufacturer, etc.

For metal punching / metal stamping / metal pressing cases, we could offer you best solution with whole production line including uncoiler, straightener, servo coil feeder, power press machine and progressive molds. The machines choosing will be according to your metal coil's specification and the technical requirement of your product. Our tooling engineer will design mold for you according to the CAD drawings or samples of your metal parts. After stamping tooling designed, we will know the tonnage and type of mechanical press machine you required and the sized of metal coils you need.

Our machines has been exported to many countries and areas so that if you need to have a inspection of our metal stamping equipment, you may visit our clients' factory under their permission.

Also we will test and do 100% inspection of our machines before shipment.

Your visiting to our factory are warmly welcomed.