GL decoiler straightener machine for coil feeding line

- Model

- GL

Item specifics

- Function

- 2 in 1 straightener machine

- Feature

- auto decoiler straightener

- Name

- automatic sheet metal straightener

- Compact

- power press mechanical feeder

- Usage

- straightener uncoiler

- attribute

- motorized uncoiler

Review

Description

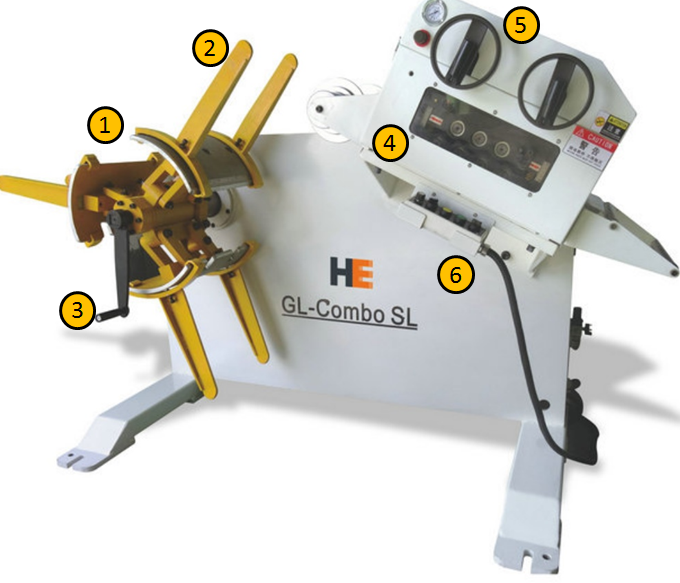

GL decoiler straightener machine for coil feeding line

Description

Decoiler Straightener

1, Decoiler for coil unwinding;

2, Coil keeper to allocate the coil sheet;

3, Manul expansion, and hydraulic expansion is optional;

4, Straightener to make coil strip flatness;

5, Worm & gear adjustment to adjust the gap between straightener rollers, which makes operation easier and more precision performance;

6, Control handle to operate uncoiler straightener machine.

specification

Model |

GL-200 | GL-300 | GL-400 |

GL-500 |

GL-600 |

Coil width(mm) | 200 | 300 | 400 | 500 | 600 |

Coil thickness(mm) |

0.3-3.2 |

||||

Coil weight(kg) | 600 | 1000 | 1500 | 2000 | 2000 |

Coil I.D(mm) | 460-520 | ||||

Coil O.D(mm) | 1200 | ||||

Speed(m/min) |

15 |

||||

Straightener roller |

4 on top / 3 on bottom Bottm rollers have drive function |

||||

Pinch roller | Inlet: 2 / Outlet: 2 | ||||

Motor(KW) | 1 | 2 | 2 | 3 | 3 |

Mandrel Expansion | Manul or hydraulic | ||||

Application

GL unwinder straightener machine which is widely used in metal sheet steel coil feeding line for punching. It is popular in electric appliance, construction, furniture industry, clothing metal parts etc.

GL

with servo feeder for coil handling

exported to Sudan

for licence plate stamping

Metal stamping solution suggestion:

GL+ NC servo feeder + Press

GL

GL decoiler straightener

for unwinding and flatness

of metal sheet coil compacted

with 80 Ton press machine

exported to France

Metal stamping solution suggestion:

GL+ NC servo feeder + Press

Solution suggestion

Package & Delivery