GL Decoiler Straightener Machine Compact Servo Feeder With Press For Hole Punching Before Forming

- Model

- GL-200

Item specifics

- Function

- combined decoiler straightener machine

- Feature

- 2 in 1 uncoiler straightener machine for feeding

- Name

- Decoiler straightener machine for feeding

- Compact

- automatic coil feeder machine

- Usage

- decoiling and straightening for metal decoiling

- attribute

- by inverter controlled

Review

Description

GL Decoiler Straightener Machine Compact Servo Feeder With Press For Hole Punching Before Forming

Description

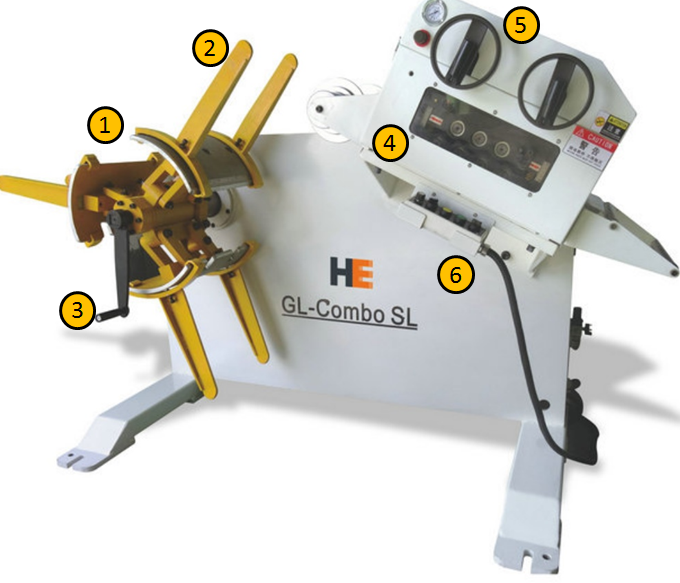

Decoiler Straightener

1, Decoiler for coil unwinding;

2, Coil keeper to allocate the coil sheet;

3, Manul expansion, and hydraulic expansion is optional;

4, Straightener to make coil strip flatness;

5, Worm & gear adjustment to adjust the gap between straightener rollers, which makes operation easier and more precision performance;

6, Control handle to operate uncoiler straightener machine.

specification

Model |

GL-200 | GL-300 | GL-400 |

GL-500 |

GL-600 |

Coil width(mm) | 200 | 300 | 400 | 500 | 600 |

Coil thickness(mm) |

0.3-3.5 |

||||

Coil weight(kg) | 600 | 1000 | 1500 | 2000 | 2000 |

Coil I.D(mm) | 460-520 | ||||

Coil O.D(mm) | 1200 | ||||

Speed(m/min) |

15 |

||||

Straightener roller |

4 on top / 3 on bottom Bottm rollers have drive function |

||||

Pinch roller | Inlet: 2 / Outlet: 2 | ||||

Motor(KW) | 1 | 2 | 2 | 3 | 3 |

Mandrel Expansion | Manul or hydraulic | ||||

Feature

2 in 1 decoiler straightener machine

1, compact with servo feeder machine

2, with uncoiling and straightening function

3, straightening with motor driven

4, with frequency inverter to control speed

5, pressing arm to be composed if metal coil thickness is above 2.0mm

6, manual or hydraulic expansion of decoiler section

Application Case

GL 2 in 1 uncoiler straightener in Indonesia

It is equipped with servo coil feeder machine and press for hole punching.

Metal stamping solution suggestion:

GL+ NC servo coil feeder + Press

Solution suggestion

Package & Delivery