GL-200 2 in 1 Decoiler Straightener Combo machine working with coil feeder and press machine

- Model

- GL-200

Item specifics

- Function

- uncoiler straightener combo machine

- Feature

- automatic uncoiling and straightening

- Name

- unwinder and leveler compact machine

- Compact

- metal coil servo coil feeder machine

- Usage

- dereeler and straightener combo in press room

- attribute

- by inverter controlled with press arm

Review

Description

GL-200 Decoiler Straightener Combo Machine For Metal Stamping Line

GL-200 Combination Decoiler Straightener is used for decoiling the metal coil strip for the press machine in the metal stamping line.

GL-200 is suitable for handling the sheet metal coil from thickness 0.3mm to 3.5mm.

With pneumatic pressure on straightener roller and worm gear adjusting, it can achieve precision straightening performance for many different kind of material.

The combined structure guarantee a synchronization between decoiler and straightener and save work space.

Description

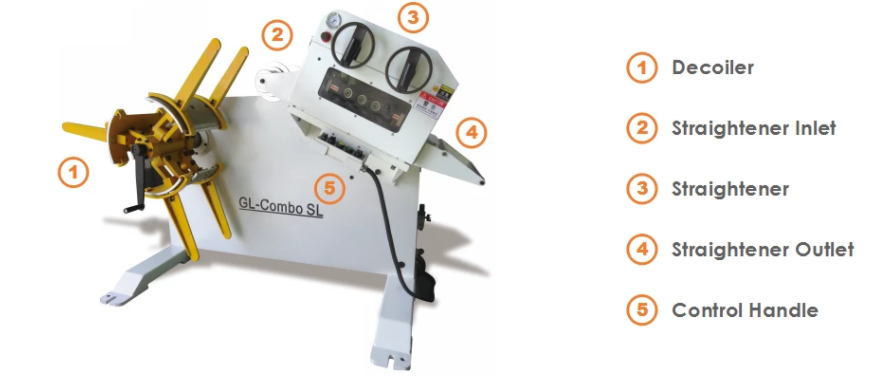

Decoiler Straightener Combo GL-200

1, Decoiler metal coil for press feeding;

2, The inlet with inverter and protect the motor;

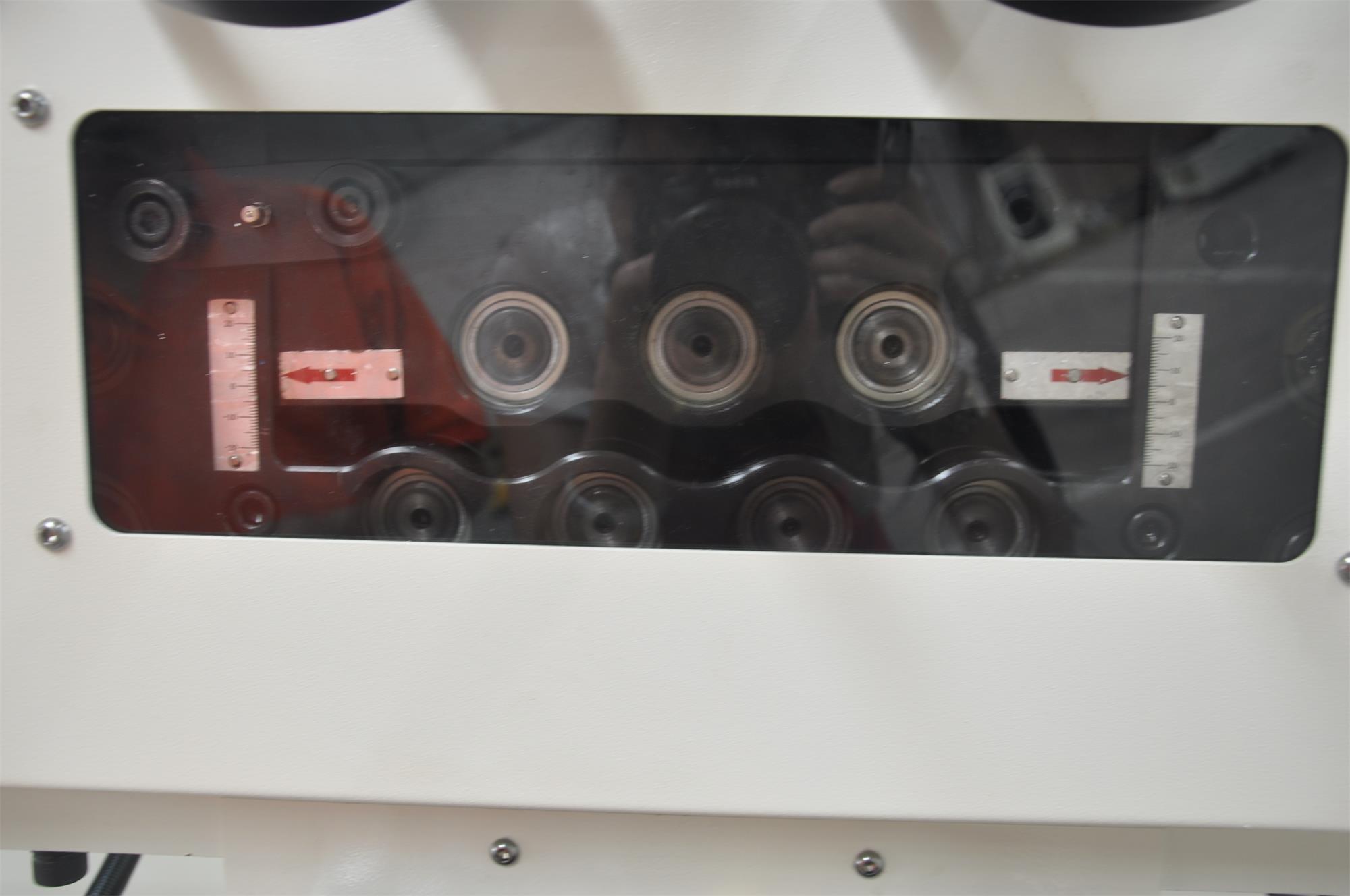

3, Straightener with 7 pcs of roll, 4 pcs on top and 3 pcs on bottom;

4, Worm & gear adjustment, easy to operate and more precision performance;

6, Hand panel to operate uncoiler straightener machine.

Specification

Model |

GL-200 | GL-300 | GL-400 |

GL-500 |

GL-600 |

Coil width(mm) | 200 | 300 | 400 | 500 | 600 |

Coil thickness(mm) |

0.3-3.2 |

||||

Coil weight(kg) | 600 | 1000 | 1500 | 2000 | 2000 |

Coil I.D(mm) | 460-520 | ||||

Coil O.D(mm) | 1200 | ||||

Speed(m/min) |

15 |

||||

Straightener roller |

4 on top / 3 on bottom Bottm rollers have drive function |

||||

Pinch roller | Inlet: 2 / Outlet: 2 | ||||

Motor(KW) | 1 | 2 | 2 | 3 | 3 |

Mandrel Expansion | Manul or hydraulic | ||||

Application

The decoiler straightener combo GL-200 is suitable for uncoiling and levelling the metal coil with width 200 mm and thickness 0.3-3.2mm. It is equiped with inverter at the inlet and protect the motor for long life service. With the combo structure, the coil decoiling and straightening is highly synchronized and working with high prevision. Comparing with the seprated machine as decoiler and feeder, it only take 7 meters. The separated ones need more than 10 meters.

GL-200

exported to Indonsia.

Metal stamping solution suggestion:

Uncoiler straightener + NC servo coil feeder + Press

Solution Suggestion

Package & Delivery