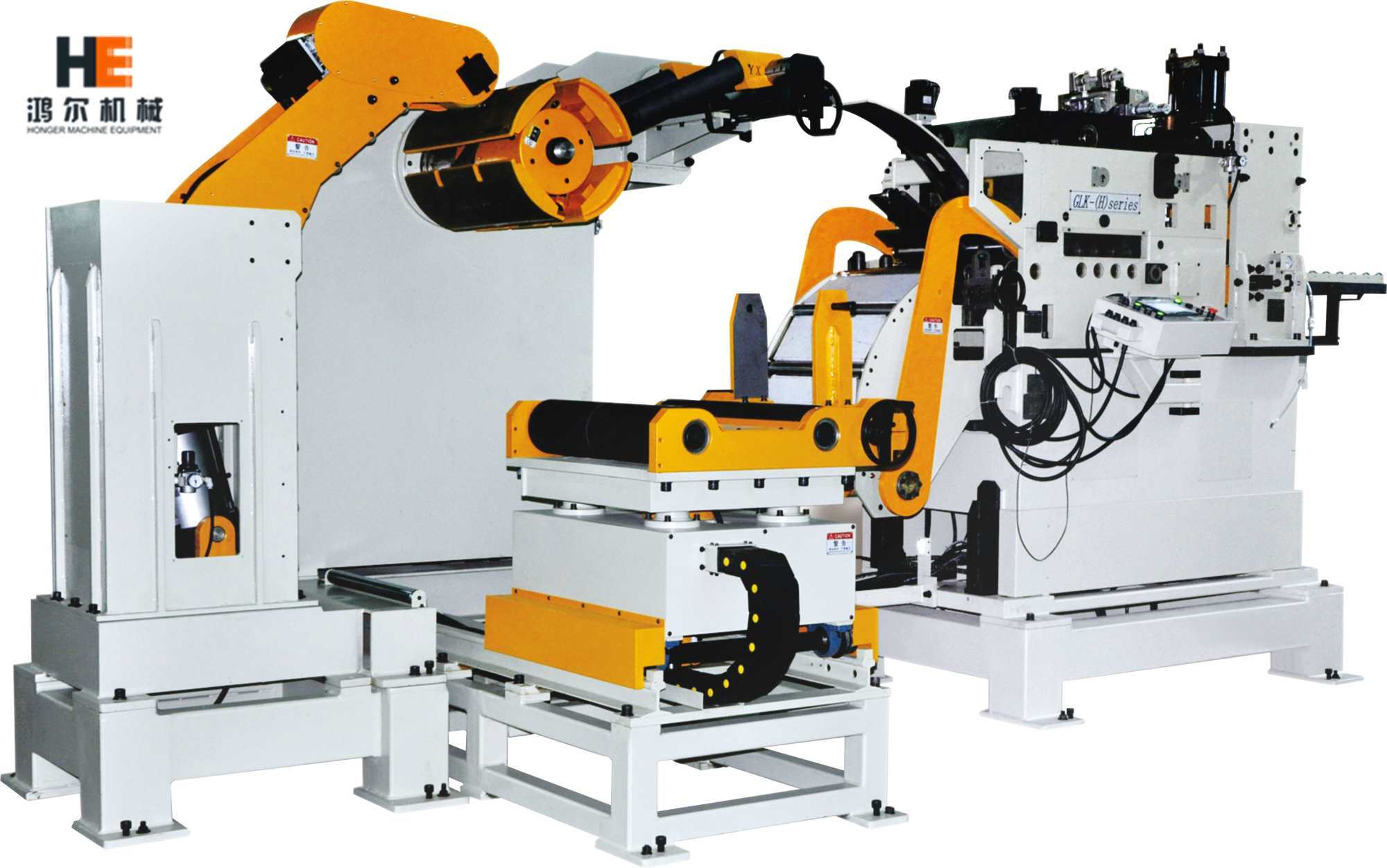

GLK4-H High Strength Servo Feeder for Metal Auto Parts Pressing

- Model

- GLK4-H

Item specifics

- Function

- servo feeding for high strength coil

- Feature

- thick metal coil handling

- Name

- 3 in 1 decoiler straightener feeder

- Compact

- large tonnage press machine

- Usage

- automotive stamping

- attribute

- uncoiling straightening with auto feeder system

Review

Description

GLK4-H High Strength Servo Feeder for Metal Auto Parts Pressing

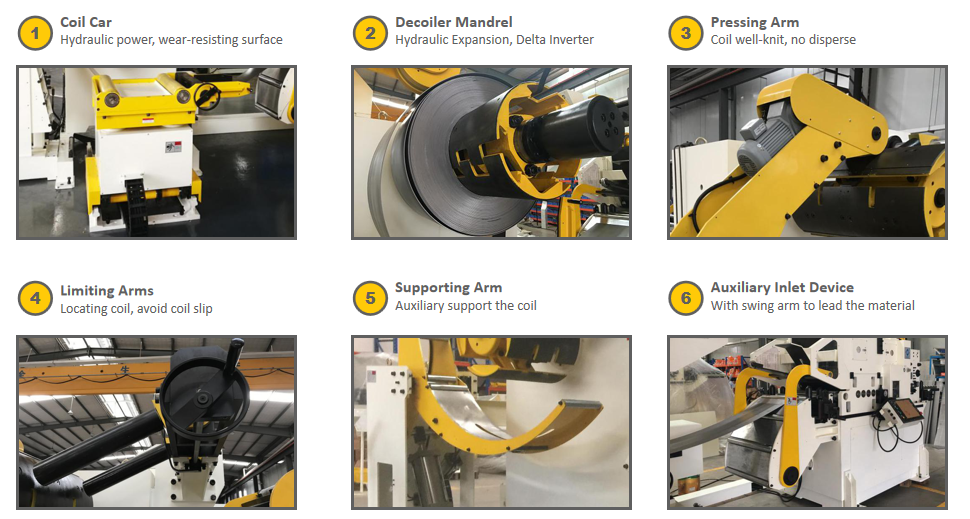

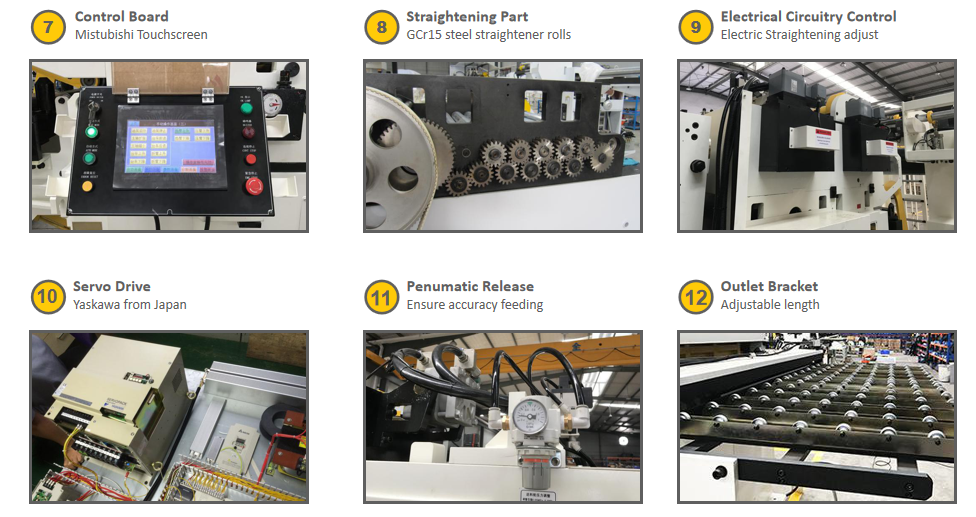

Photo show

Description

specification

Model |

GLK4-600H | GLK4-800H | GLK4-1000H | GLK4-1300H |

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | |||

Coil width(mm) |

70-600 | 70-800 | 70-1000 | 70-1300 |

Coil thickness | 0.6-6.0mm | |||

Coil weight | 5000kg | 5000kg | 7000kg | 10000kg |

Coil I.D.(mm) |

480-520 |

|||

Coil O.D.(mm) |

1400 |

|||

Max. speed | 16-24 m/min | |||

Feeding accuracy | +/- 0.15 mm | |||

Straightener rollers | 4 rollers on top 3 rollers on bottom | |||

Auxiliary Rolls | Φ68mm * 220mm *(1-3) groups | |||

Power | 380V 60HZ | |||

Expansion | Hydraulic | |||

Pressing arm | Pneumatic Type | |||

Servo motor | AC15.0 | AC15.0 | AC15.0 | AC22 |

Uncoiler motor | AC2.2 | AC2.2 | AC3.7 | AC7.5 |

Application

GLK4-H decoiler straightener feeder machine works for high yield strength metal coils. This 3 in 1 automatic coil feeder is compact with press machine for metal stamping, especially widely used in automobile industry for auto parts stamping.

GLK4-H

High strength 3 in 1 servo feeder machine

working for automotive stamping

exported to Malaysia

Solution Suggestion:

3 in 1 decoiler straightener feeder + press

GLK4-H

3 in 1 compacted coil feeder

equipped with large tonnage press machine

for automotive Tier 1 stamping

in Wuhan

Solution Suggestion:

3 in 1 decoiler straightener feeder + press

Package & Delivery