GLK4-800H High Strength Servo Coil Feeder For Thicker Metal Coil Sheet Feeding Line In Press Room

- Model

- GLK4-1600H

Item specifics

- Function

- servo feeding for high strength coil

- Feature

- high yield strength metal coil handling

- Name

- 3 in 1 decoiler straightener feeder

- Compact

- large tonnage press machine

- Usage

- automotive stamping

- attribute

- uncoiling straightening with auto feeder system

Review

Description

GLK4-800H High Strength Servo Coil Feeder For Thicker Metal Coil Sheet Feeding Line In Press Room

Photo show

Description

specification

Model |

GLK4-800H |

|||

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | |||

Coil width(mm) |

70-800 |

|||

Coil thickness | 0.6-6.0mm | |||

Coil weight | 7000kg | |||

Coil I.D.(mm) |

480-520 |

|||

Coil O.D.(mm) |

1400-1800 |

|||

Max. speed | 16-24 m/min | |||

Feeding accuracy | +/- 0.15 mm | |||

Straightener rollers | 4 rollers on top 3 rollers on bottom | |||

Auxiliary Rolls | Φ68mm * 220mm *(1-3) groups | |||

Power | 380V 60HZ | |||

Expansion | Hydraulic | |||

Pressing arm | Pneumatic Type | |||

Servo motor | AC11.0 | |||

Uncoiler motor | AC3.7 | |||

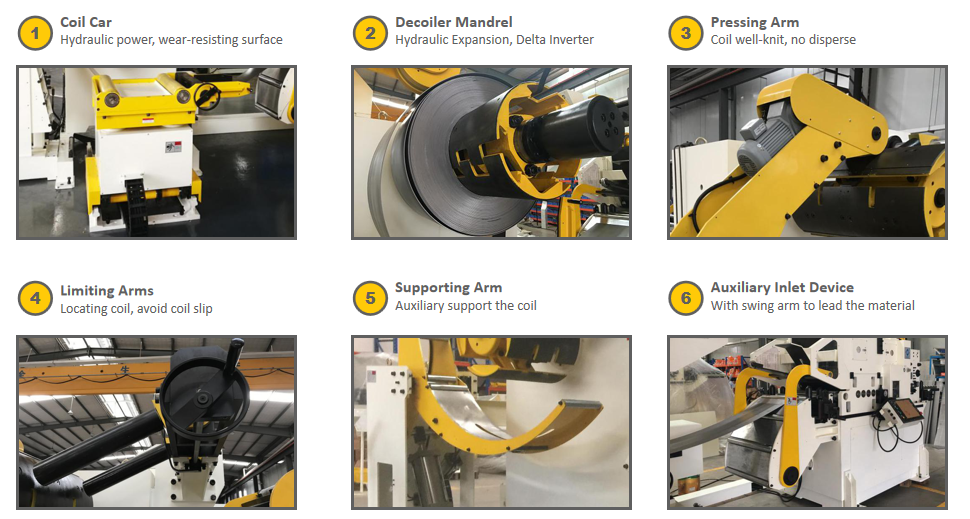

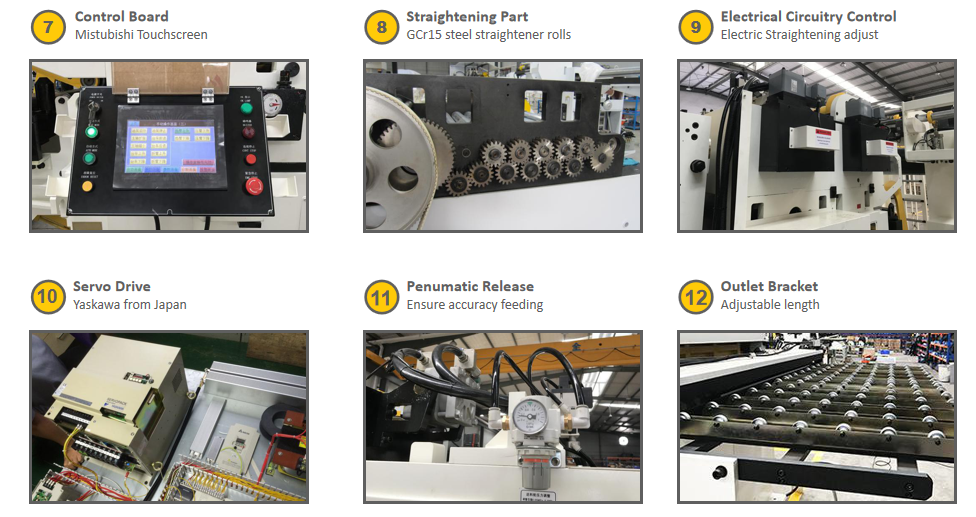

Features

GLK-H high strength coil feeder machine:

1, work for metal coils with OD 1400mm to 1800mm

2, suitable for metal coil with thickness 0.6-6.0mm

3, mandrel is wedge type, which is more powerful than connecting rod type

4, pressing arm with pneumatic type or hydraulic

5, supporting arm to protect decoiler mandrel

6, coil car assist to load metal coil

7, coil keeper with wheel adjustment or customized as electrical adjustment

8, inlet arm with hydraulic power to put coil head into straightener feeder

9, straightener roller adjusted by electrical control

10, feeding height adjusted by electrical control

11, all rollers electroplated with chrom to achieve HRC 60-62 hardness, and tested by the concentricity with +/-0.005mm accuracy

12, the down straightener rollers transmission by double row chain

13, all gears are subject to high precision grinding

14, auxiliary roller to prevent straightener rollers from transform after long using time and make sure high straightening performance15, straighener and feeder section share the servo motor with high precision

16, hydraulic shearing is optional, which is used to cut head of coil

17, lubrication device is optional, which is used to protect press tooling

18, larger and thicker frame body is subject to sand blasting with over 10 years service life

19, combine decoiler, straightener and servo feeder to save work space

20, used in automation feeding line to handle with metal coils in press room

Application

GLK4-800H high strength servo coil feeder machine is suitable for 800mm width metal coil sheet with thickness 0.6-6.0mm. It is larger and stronger than standard 3 in 1 coil feeder and widely used in automobile industry for automation feeding.

GLK4-800H

3 in 1 high strength coil feeder unit machine

exported to UK

for Jaguar auto parts stamping

Solution Suggestion:

combine decoiler straightener feeder + mechanical press machine

Package & Delivery

About us

We are manufacturer of metal stamping equipment like decoiler, straightener, feeder machine for metal coil handling solution in press room.

Our equipment is for automation feeding system in press room to realize automatic stamping.

The related machines of us are including 3 in 1 unit coil feeder, 2 in 1 uncoiler and straightener machine, single decoiler machine, horizontal uncoiler machine, straightener machine, servo coil feeder machine, mechanical press machine, etc.

Our machines are adopted in automotive stamping manufacturer ( automobile manufacturer), construction metal parts manufacturer, furniture metal parts manufacturer, kitchen ware metal parts manufacturer, costume eyelet ( button) manufacturer, electronic parts stamping manufacturer, etc.

For metal punching / metal stamping / metal pressing cases, we could offer you best solution with whole production line including uncoiler, straightener, servo coil feeder, power press machine and progressive molds. The machines choosing will be according to your metal coil's specification and the technical requirement of your product. Our tooling engineer will design mold for you according to the CAD drawings or samples of your metal parts. After stamping tooling designed, we will know the tonnage and type of mechanical press machine you required and the sized of metal coils you need.

Our machines has been exported to many countries and areas so that if you need to have a inspection of our metal stamping equipment, you may visit our clients' factory under their permission.

Also we will test and do 100% inspection of our machines before shipment.

Your visiting to our factory are warmly welcomed.