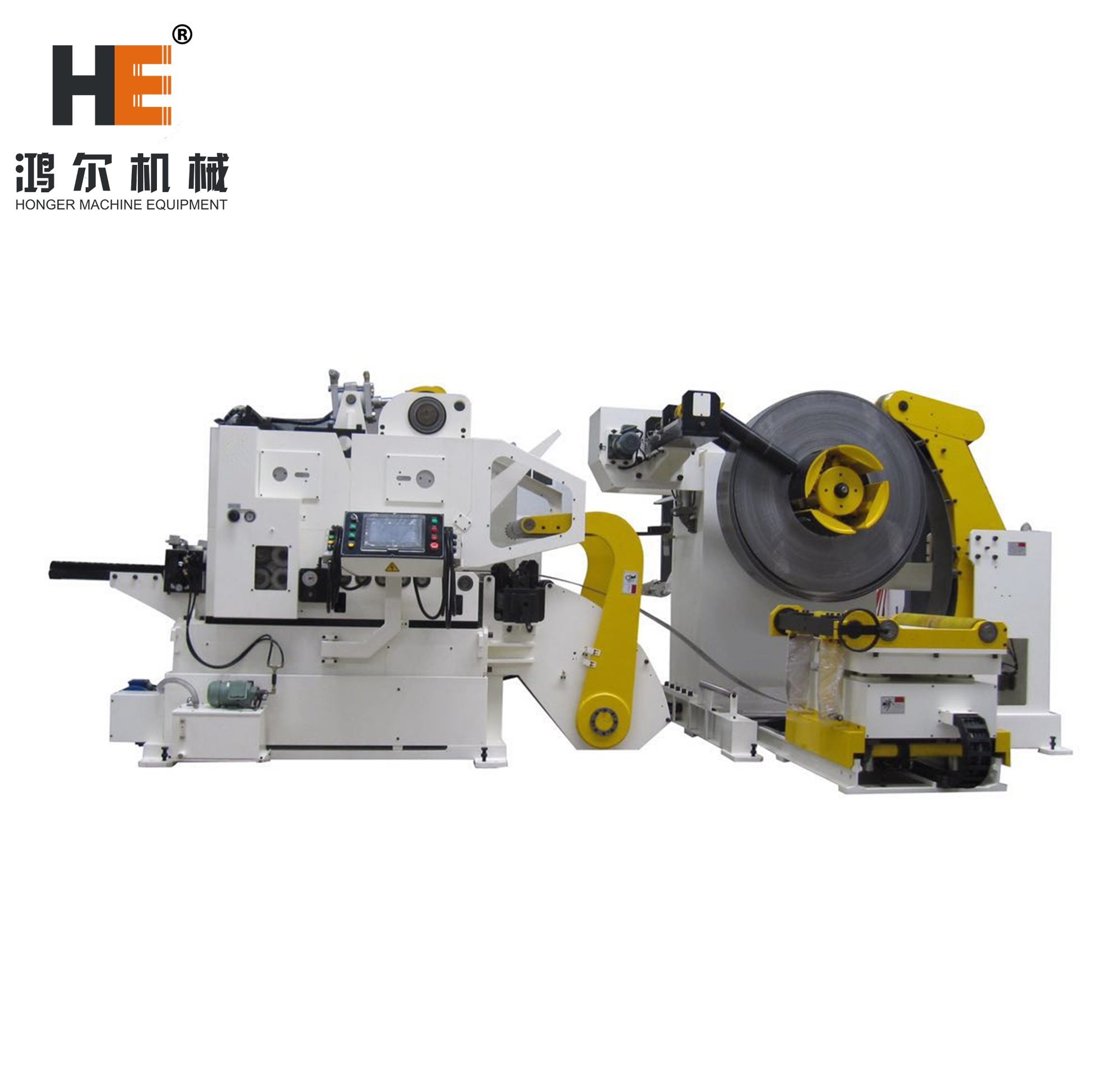

GLK5-800 Coil Servo Feeder for Automation Feeding System In Press Room For 0.8-9.0mm Thickness Coil

- Model

- GLK5-800

Item specifics

- Function

- automatic feeding for metal coil sheet

- Feature

- decoiling straightening and feeding

- Name

- 3 in 1 servo coil feeder for metal stamping

- Compact

- press machine

- Usage

- metal coil handling

- attribute

- automatic feeding line

Review

Description

GLK5-800 Coil Servo Feeder for Automation Feeding System In Press Room For 0.8-9.0mm Thickness Coil

Photo show

Description

Features & Funtions

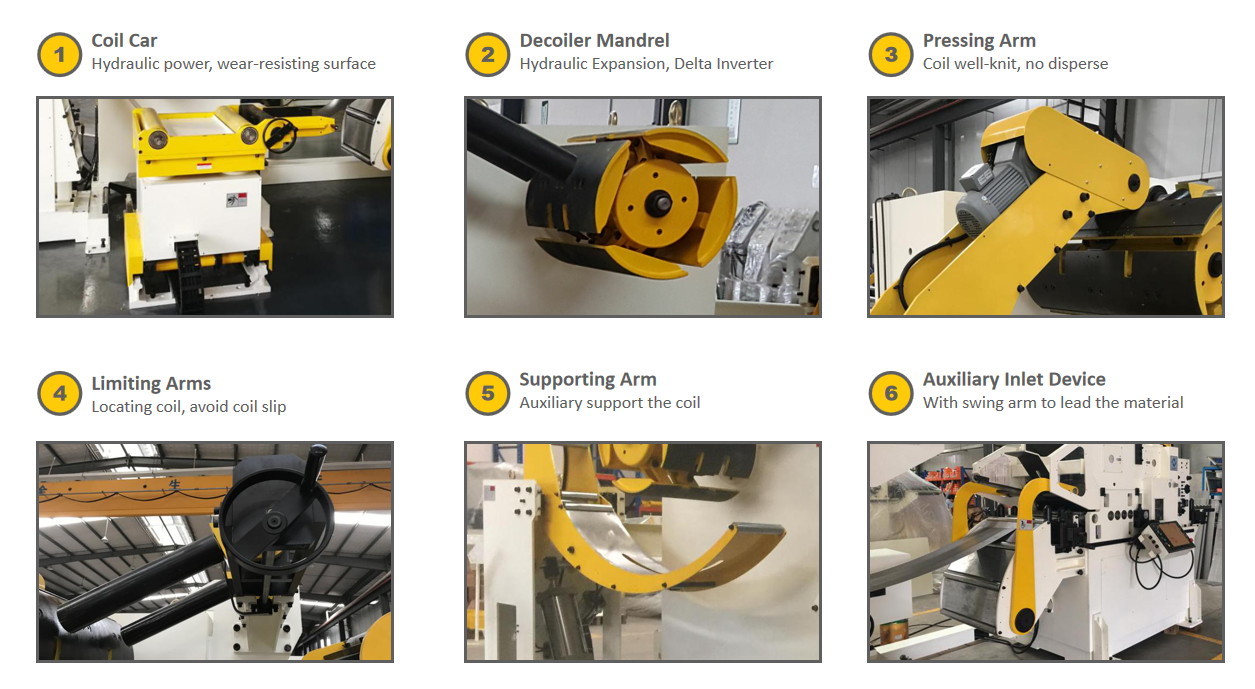

Decoiler

①, Decoiler mandrel loading width 70-800mm, loading weight 5000kgs

②, Expansion: Hydraulic connecting rod type, expansion range Φ475mm-Φ520mm

③, Drive Motor: AC gear motor, with inverter control

④, Driving Method: Big pitch double-row chain transmission

⑤, Brake Mode: Pneumatic disc brake

⑥, Uncoiling Direction: Counterclockwise

⑦, Pressing Arm: Add pressure on coil, prevent coil disperse, open/close by hydraulic ( PU wheel, 1pc). It is selective used when automatic operation.

⑧, Limiting Arms: Locating coil, prevent coil slip, open/close by air cylinder, distance between arms adjusted by hand wheel(electronic adjustment can be customized)

⑨, Supporting Arm: Auxiliary support the metal strip go to straightening part, powered by air cylinder

⑩, Loop control by photoelectric sensor

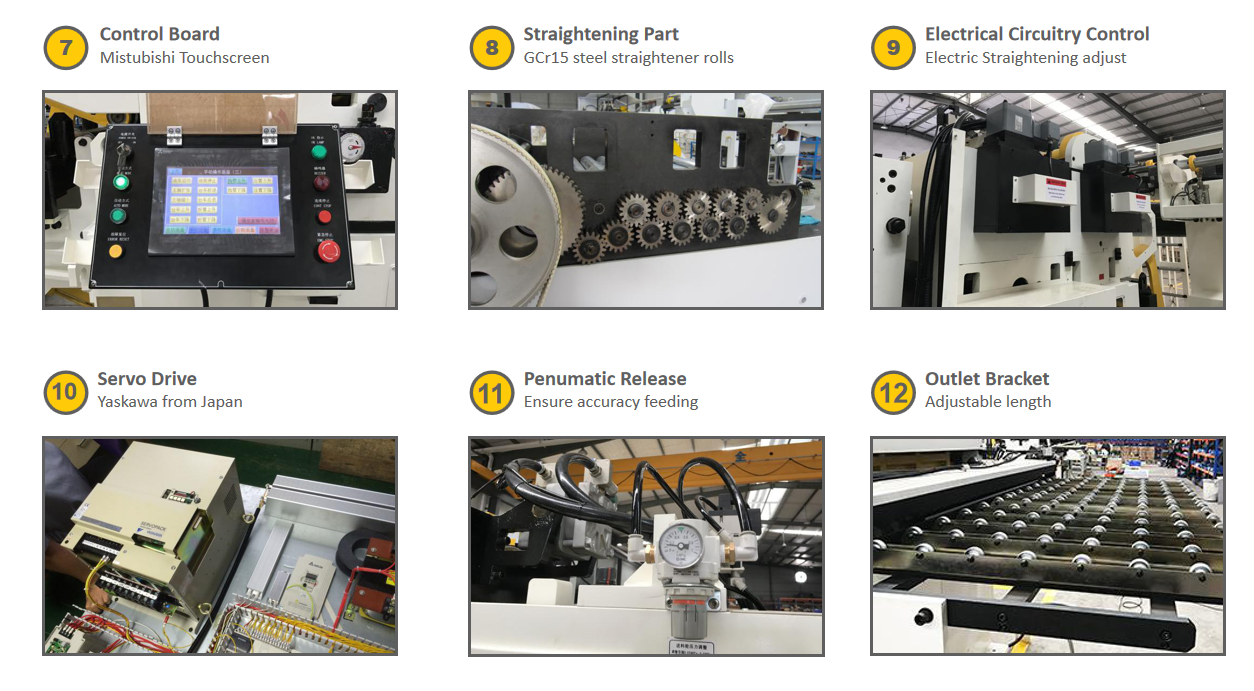

Straightener Feeder

①, Straightening Rolls: Φ88mm*12pcs (up6/down6)

②, Auxiliary Rolls: 1 group (up6/down5 for each group)

③, Feeding Rolls: 2pcs

④, Rolls Drive: Side gear drive

⑤, Straightening Rolls Support: Deep groove ball bearing

⑥, Straightening Rolls Release: Pneumatic type

⑦, Drive Method: AC servo motor, 15Kw

⑧, Straightening Pressure: Electric adjustment, displayed by dial scale, setting precision 0.1mm

Feeding Precision: ±0.15mm when feeding length 500mm

⑨, Max. Feeding Speed: 22m/min

⑩, Feeding Height Adjustment: Electric adjustment

specification

Model |

GLK5-600 | GLK5-800 | GLK5-1000 | GLK5-1300 |

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | |||

Coil width(mm) |

70-600 | 70-800 | 70-1000 | 70-1300 |

Coil thickness | 0.8-9.0mm | |||

Coil weight | 5000kg | 5000kg | 7000kg | 10000kg |

Coil I.D.(mm) |

480-520 |

|||

Coil O.D.(mm) |

1400 |

|||

Max. speed | 16-24 m/min | |||

Feeding accuracy | +/- 0.15 mm | |||

Straightener rollers | Φ88mm*12pcs: 6 rollers on top 6 rollers on bottom | |||

Auxiliary Rolls | Φ68mm * 220mm *(1-3) groups | |||

Power | 380V 60HZ | |||

Expansion | Hydraulic | |||

Pressing arm | Hydraulic Type | |||

Servo motor | AC15.0 | AC15.0 | AC15.0 | AC22 |

Uncoiler motor | AC2.2 | AC2.2 | AC3.7 | AC7.5 |

Application

GLK5 series decoiler straightener feeder machine works for 0.8-9.0mm thickness metal coils in pressing room to realize automation feeding. This 3 in 1 coil feeder machine is used for metal stamping line equipped with injection mold in press machine. It is often worked for metal coil handling in automotive/ automobile stamping manufacturers.

GLK5-800

3 in 1 automatic servo coil feeder in press room

working for auto parts stamping

delivered to Wuhan

Solution Suggestion:

3 in 1 decoiler straightener feeder + press

Package & Delivery